Manufacturing : Predictive Maintenance

Predictive Maintenance

A global manufacturing company specializes in manufacturing of industrial goods and equipment wanted to reduce the breakdown maintenance and reduce operations cost.

A manufacturing predictive maintenance solution using Amazon SageMaker Services can help manufacturing companies reduce equipment downtime and optimize maintenance schedules by predicting when maintenance is required.

Solutions

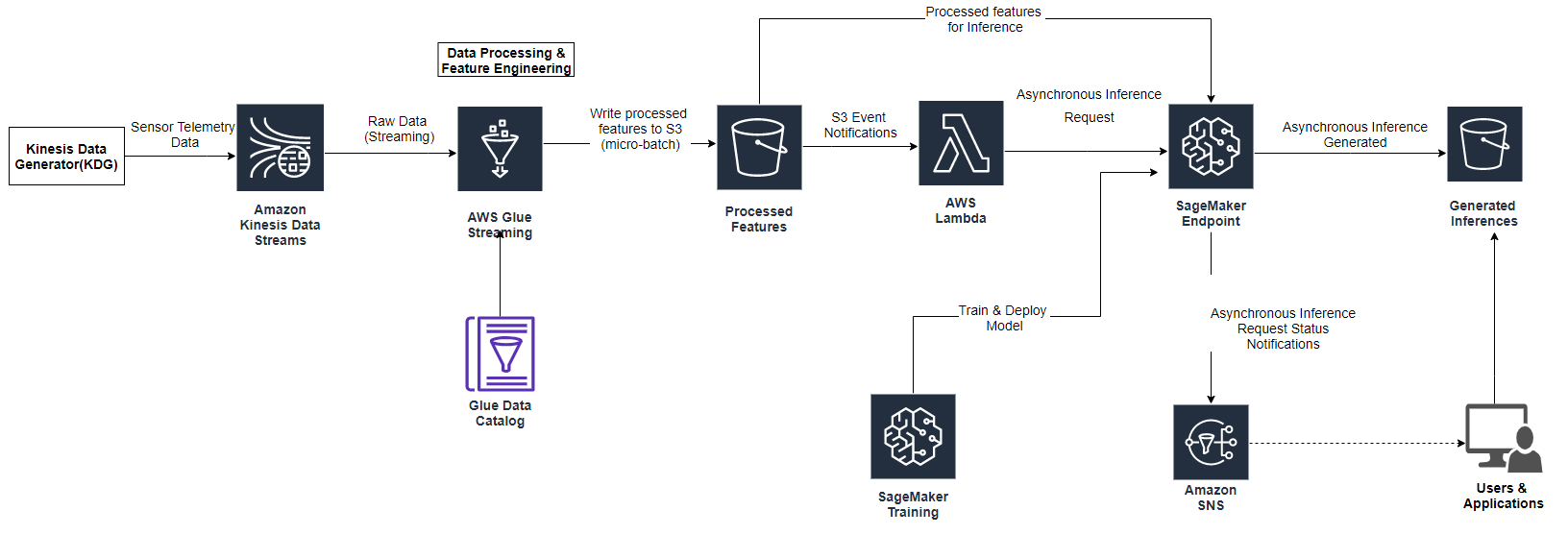

- Data Collection: Data is collected from various sources, such as IoT sensors, equipment logs, and maintenance records, and stored in Amazon S3 buckets.

- Data Preparation: The collected data is cleaned, transformed, and prepared for analysis using AWS Glue. Glue can be used to automate the data preparation process, making it easier to manage and scale.

- Feature Engineering: Amazon SageMaker is used to create features from the prepared data. Feature engineering is the process of selecting the most relevant data features and transforming them into a format that can be used for machine learning.

- Model Training: SageMaker is used to train a machine learning model using the features generated in the previous step. The model can predict when equipment failure is likely to occur, enabling maintenance teams to take proactive action to avoid equipment downtime.

- Model Deployment: The trained model is deployed as a web service using SageMaker. The web service can be accessed by other applications and services to perform real-time predictive maintenance.

- Alerting: The results of the predictive maintenance model are used to generate alerts using AWS Lambda functions. These alerts can be sent to maintenance teams, enabling them to take proactive action to avoid equipment downtime.

- Root Cause Analysis: Amazon QuickSight is used to analyze the maintenance records and equipment logs to identify the root cause of the predicted equipment failure. This information can be used to optimize maintenance schedules and improve equipment performance.

Benefits:

- Reduction in the breakdown maintenance incidents by 54%

- Reduction in the operations cost for machine maintenance by 23%

- Improved safety leading to better compliance to sustainability goals of organization